Identify Electrical Faults Before They Become Problems

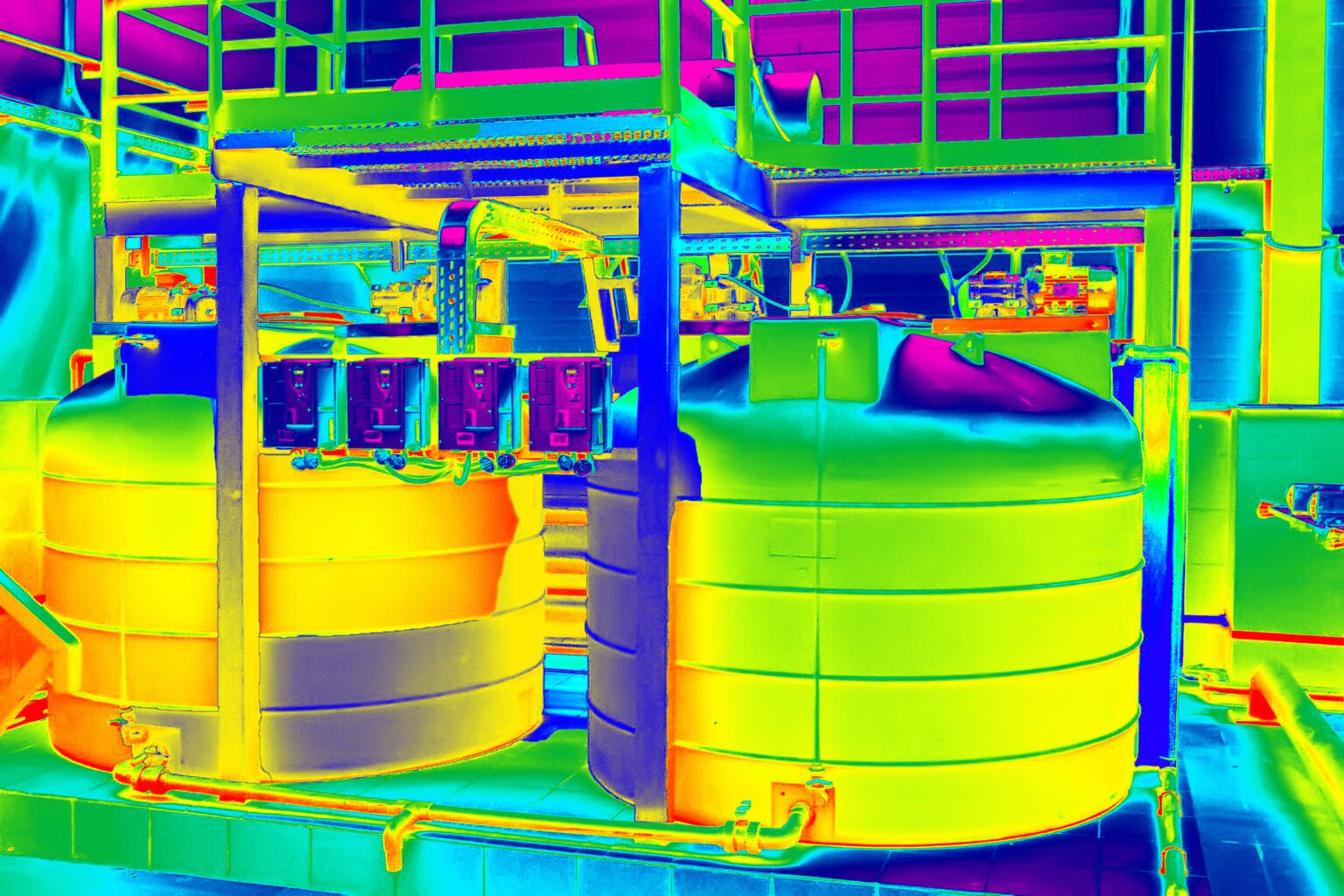

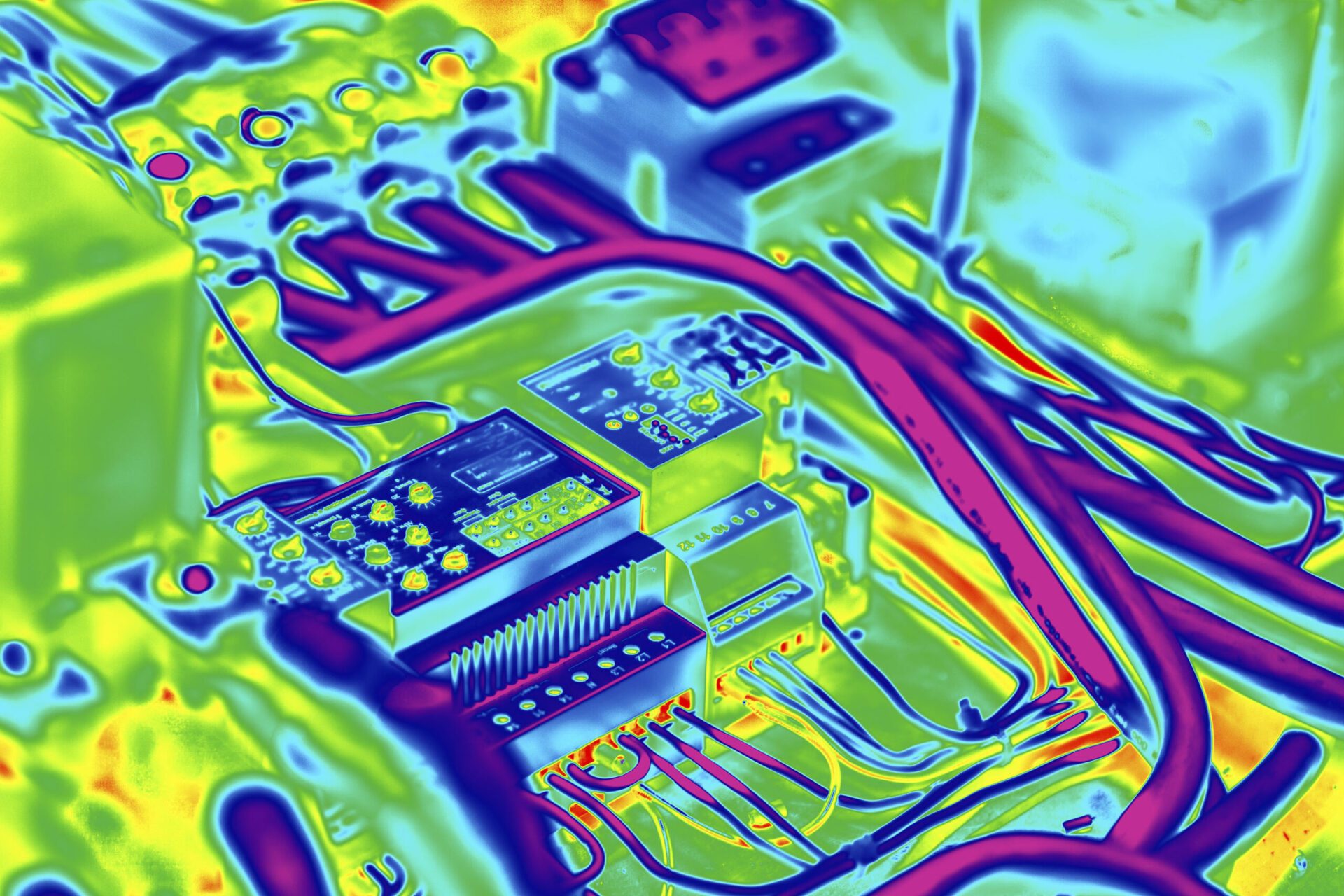

At GLS Electrical, thermographic scanning is part of how we keep people and properties safe. Using a thermal imaging camera, we’re able to detect abnormal heat in electrical systems—often long before anything visibly goes wrong.

These scans are especially useful in commercial and industrial settings, where a fault in wiring, switchboards, or equipment can be costly—not just in repairs, but in downtime too. Thermal imaging allows us to spot overheating connections, unbalanced loads, loose terminals, or failing components without interrupting your operations. It’s non-invasive, fast, and doesn’t require shutting down power.

What is Thermographic Scanning?

Thermographic scanning, also called thermal imaging, is a method of identifying temperature differences in electrical components. Every piece of electrical equipment produces heat as it operates. But when something starts to go wrong—like a connection becomes loose or a circuit gets overloaded—it gives off more heat than usual.

We use specialised infrared cameras to pick up those hotspots. From there, we can investigate further and recommend repairs or replacements before the issue turns into a breakdown or a fire risk.